AeroBarrier with Absolute Efficiency Group

Seal The Gap Our air sealing system seals all building envelope leaks up to ½”, and as small as a human hair. [image: waterbased-icon]

![]()

Waterborne Acrylic Seal

GreenGuard Gold certified, the sealant is self-guided to the edges of leaks creating a seal.

![]()

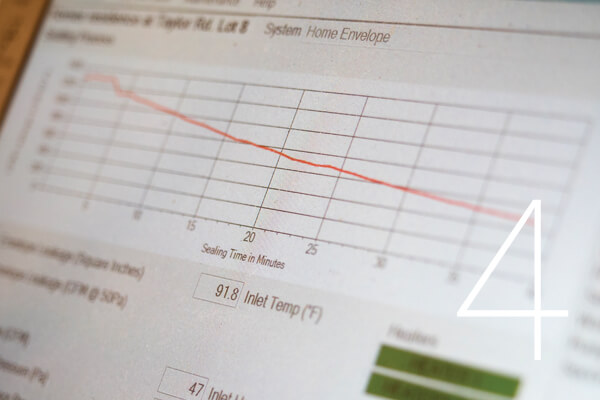

Real-Time Updates

Using a standard, single-point blower door test, our software measures the leakage in real time.

![]()

Meet Requirements

Real-time measurements enable you to dial in specific requirements and guarantee the results.

WE GUARANTEE AIR SEALING RESULTS IN 4 EASY STEPS

STEP 1 PREP & SETUP

Prep the area by covering any openings that won’t be sealed. This includes taping or covering any designed openings or finished horizontal surfaces within the space. Emitters are then set up throughout the area to be air sealed.

The equipment is then set up. This includes blower door, emitters, hoses, and the AeroBarrier machine.

STEP 2 PRESSURIZE & APPLY

Using a blower door, the space is pressurized. After that, a computer controls the entire process including the temperature, pressure, humidity, and distribution of sealant within sealant within the space during the process.

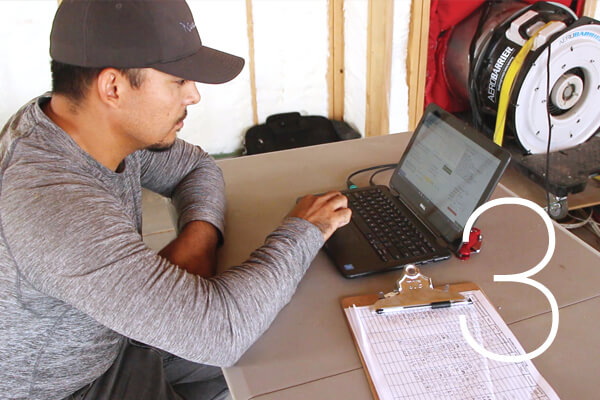

STEP 3 SEAL & MONITOR

With the AeroBarrier process, you see results in real time. You have complete control over your desired level of air tightness and can achieve any level required. At the end of the process, a final blower door test is run to verify the air sealing results. AeroBarrier then provides a Certificate of Completion that shows pre and post leakage.

STEP 4 CLEAN UP

After the air sealing is complete, work can resume in the space within 30 minutes. At that time, clean up of all equipment and removal of all tape and coverings can occur.